Ls2 Connecting Rod Torque

Connecting rod casting number last three digits 143.

Ls2 connecting rod torque. Connecting rod bolts first design first pass 15 lb ft. Connecting rod housing bore. Ls2 car rotating assembly specs. 3 small block engine from general motors used in cars from 1997 2004.

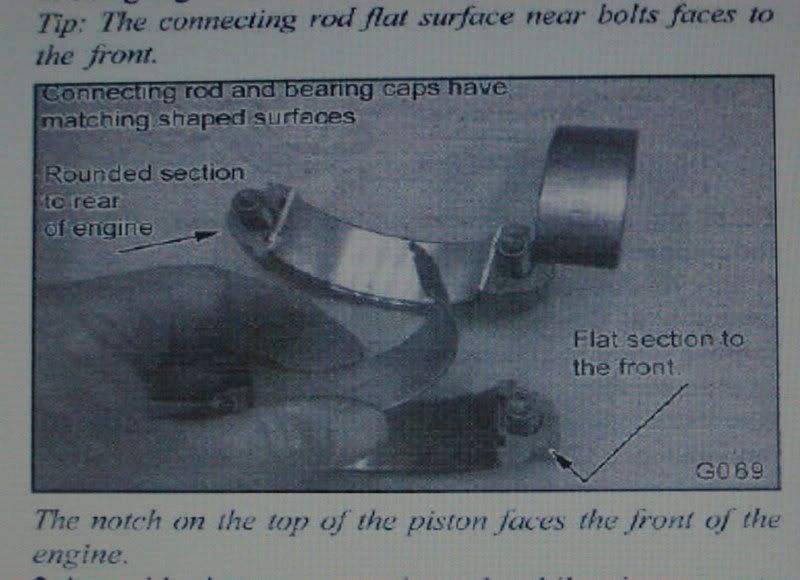

The rod bolts should continue to be tightened using twopasses advertisementclick here to read moreadvertisement the new specification calls for the second pass value to be increased from 75 to 85. Crankshaft casting number. Connecting rod bolts second design first pass 15 lb ft. Tighten connecting rod bolts torque fasteners note.

Hypereutectic cast aluminum alloy. The ls1 is the original gen. If using aftermarket rods or bolts follow the tightening procedure specified by the manufacturer and read utilizing fastener stretch below for more information. Check clearance between piston and connecting rod small end.

Connecting rod housing bore. Connecting rod bolts second design final pass 75 degrees. I made a mistake last time and said torque your mains to 45ft lbs and 55ft lbs respectively. Replacing the old tried and true small block chevy engine with a new version would not be an easy task.

M9 x 1. The new small block is known as the ls engine family and has more than successfully replaced 350 s and 305 s that were based in design from the 1950 s. I didn t sit well with me. There is a tool for this but after forty years i use my fingers.

When working on gen iii and gen iv vortec 4 8l 5 3l 5 7l 6 0l and6 2l v8 engines you should follow a new connecting rod bolt torquespecification. Full floating connecting rod material. M9 x 1 x 43. The procedures described in this step apply to engines using gm connecting rods and rod bolts only.

The engine specs and information here is for the stock ls1 engine. Connecting rod bolts first pass 20y 15lbft connecting rod bolts final pass 85degrees coolant air bleed pipe and cover bolts 12y 106lbin coolant temperature sensor 20y 15lbft crankshaft balancer bolt installation pass to ensure the balancer is completely installed 330y 240lbft crankshaft balancer bolt first pass install a new. Connecting rod bolts first design final pass 60 degrees.