M8 Cap Head Bolt Torque

Supply part number.

M8 cap head bolt torque. Torque tension reference guide printed in u s a. Metric torque chart for hex head cap screws torque chart for stainless steel cap screws size 316 i n c h 18 8 i n c h 10 1 9 6 6 40 12 7 12 1. A m30 12 9 fastener has a maximum tightening torque of 2 280 nm based on a friction coefficient of 0 125 zinc plated maximum torque. In general the proper torque spec is usually around 65 70 of the failure torque rate.

Bolt torque calculator calculate required bolt torque. M8 x 1 25 pitch 8 8 25 0 23 0 18 75 17 25. Iso 724 metric threads dimensions of metric threads according iso 724. The below chart refers to usage in steel.

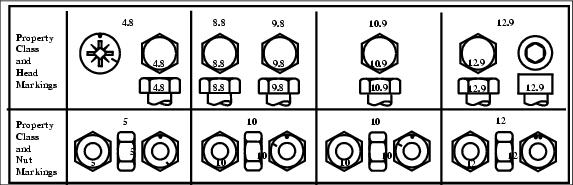

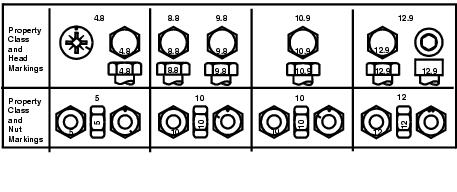

In threads per inch 307a astm a307 grade a sae j429 grade 5 sae j429 grade 8 f n l g 9 fnl grade 9 clamp load lbs tightening. M8 1 25 36 60 32 80 44 65 35 50 24 01 39 8 27 8 m10 1 50 58 00 52 30 70 76 56 26 38 28 78 8 55 1. Lubricating the bolts is the suggested method. Steel grade sae 5 sae 8 socket head cap screws property class 8 8 10 9 12 9 socket head cap screw torque in pound foot or pound inch torque in newton meter nm lubed means cleaned dry bolts lubricated with standard medium viscosity machine oil.

Lubricated bolts and reduced torque lubrication effect on bolt tension and torque. Resulting maximum pre load for standard hex head bolts and socket head cap screws based on. Lubricate all contact areas of the bolts and washers. Of the bolt proof loads specified for sae j 429 grade 5 and astm a 449 bolts.

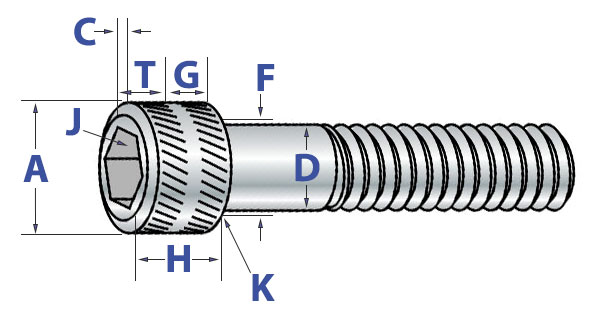

Fasteners bolts nuts and threaded rods torque tension and loads. When so specified by the purchaser the edges of holes on the outside surface of the head will be chamfered 45 degrees to a depth of 0 30 to 0 50 mm. Improvised torque wrench improvised torque wrench with luggage scale. Tightening torque tensile yield shear strength socket head cap screw socket head cap screw recommended tightening torque class 12 9 size pitch stress area core area tensile strength.

2 280nm 123 or 117.