Micro Nozzle Air Bearings

Typical application is the cooling of very hot materials surfaces vanes and holes as metal alloys aluminium magnesium alloys etc in mechanical.

Micro nozzle air bearings. Self acting micro air bearings are demanded for developing high performance maintenance free micro gas turbines. Sound level 74 dba at 3ft 0 91mm at 80 psig 5 6 bar. The advantages of the micro nozzle air bearing technology include. In contrast to conventional bearings with this technique the air bearings require no manual or costly manufacturing.

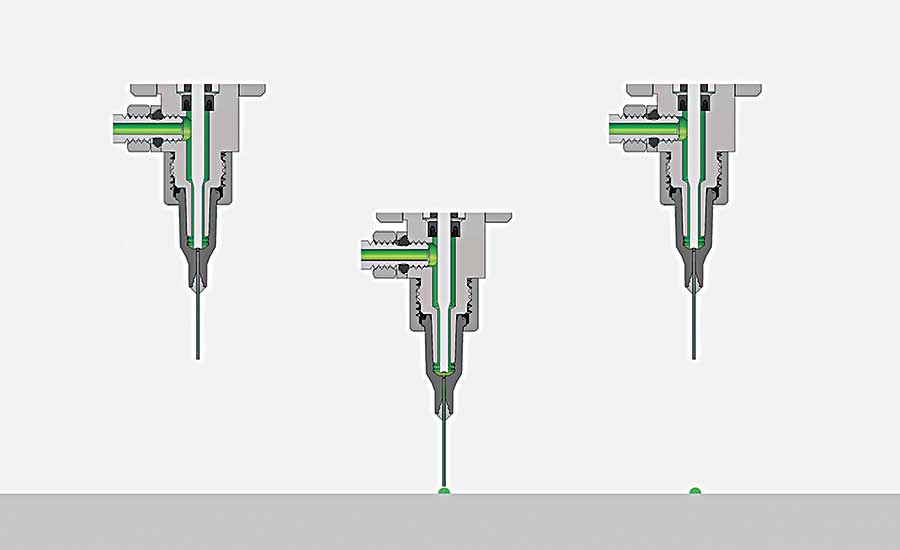

Accurate calculations ensure the perfect amount distribution and geometry of the micro nozzles. These cooling micro nozzles are suitable where a concentrate air beam must hit with energy a small area but there is a very small space to fit the nozzles as in the spindle head cooling vanes. The micro air nozzle provides powerful force within a small footprint. Small gap tight tolerance.

The lechler conticleaner is a rotating cleaning head with flat spray nozzles and slide bearings. Model 47002 is the brass nozzle added to a copper tube. Machine builders can bend the copper tube and aim the nozzles to wherever it suits. To top it off most bearings are made of high carbon steels or ceramics.

A model 1010ss 9456 includes 2 micro super air nozzles 2 stay set hoses and a magnetic base. As for the high amount of micro nozzles there is an unlimited number. Aerostatic air bearing according to claim 1 wherein the ratio of the sum of the cross sectional areas of the micro channels 131 of the micro channel system 13 leading away from the nozzle channel 12 to the area of the narrowest cross section of the nozzle channel 12 is less than 1 85 preferably is less than 1 5 more preferably. Air nozzle model.

In this study we designed and manufactured both radial and thrust foil bearings and developed two types of apparatuses for testing the performance of these bearings. Available 2 super air scraper. Model 47001 is designed to fit into small spots and is used by many machine builders for blow off applications. A liquid bearing can have a 100 µm bearing gap but an air bearing can only have a 10 µm gap with a half of a micron tolerance.

Air clean and contaminant free. In doing so we perfectly adjust our air bearings behaviors to the customer s needs. The physical behaviors of the air bearings prove to have a low variation for large as well as for small production volumes.